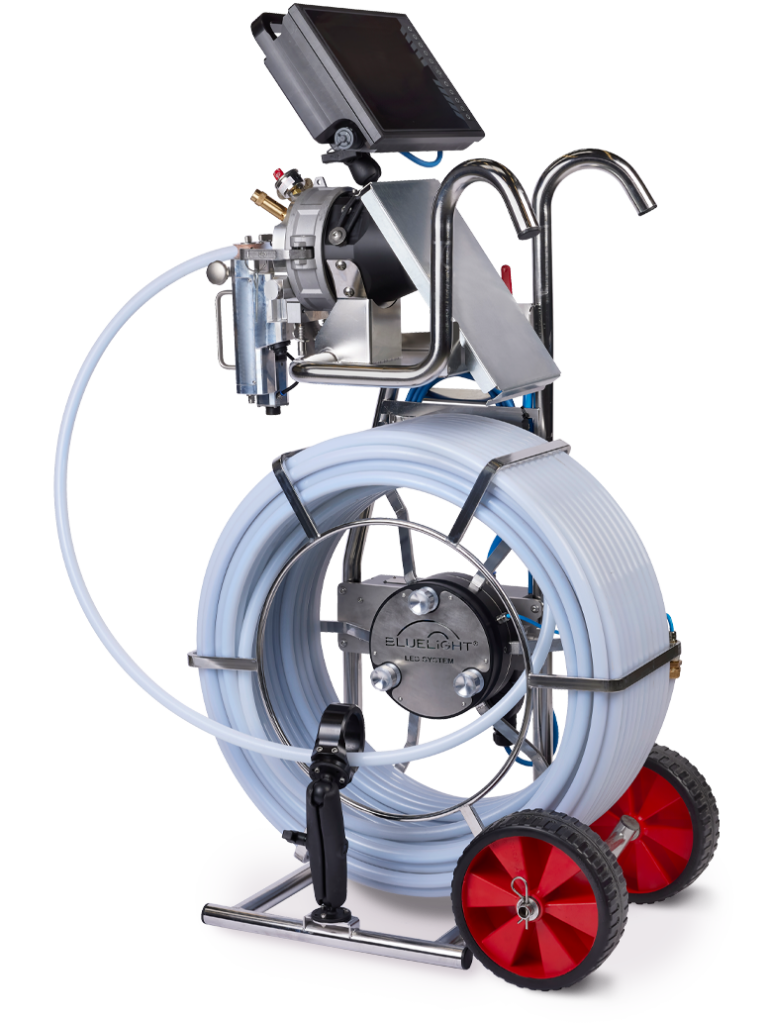

Bluelight LED system | profile

In 2008 engineers at the Denmark based company Aarsleff A/S started pioneering development with the first prototypes of small LED light sources for curing flexible CIPP in laterals. The first idea was to use the initial developments in their own contracting businesses.

In 2015 Bluelight GmbH was founded as Aarsleff’s daughter enterprise to become the B2B platform.

The groundbreaking and innovative system technology was first introduced in the German-speaking market areas. Years later the Bluelight LED system has written a great success story in the northern hemisphere.

Early 2024 the tremendous amount of more than 400 Bluelight power- and control-units are reliably operating day in day out in Europe and North America. Most units are active in core markets representing the highest quality standards in trenchless technology: in Europe Bluelight technology leads the markets by volume and quality in Germany, France, UK, Belgium, Austria, Switzerland and Scandinavia. Other southern and eastern European countries are developing positively.

Within North America – operated by distribution partner HammerHead Trenchless – Bluelight is the leader in the United States and Canada.

In Australia and New Zealand, Bluelight is distributed by partner SECA.

BLUELIGHT GmbH is a part of the Per Aarsleff A/S group.

01

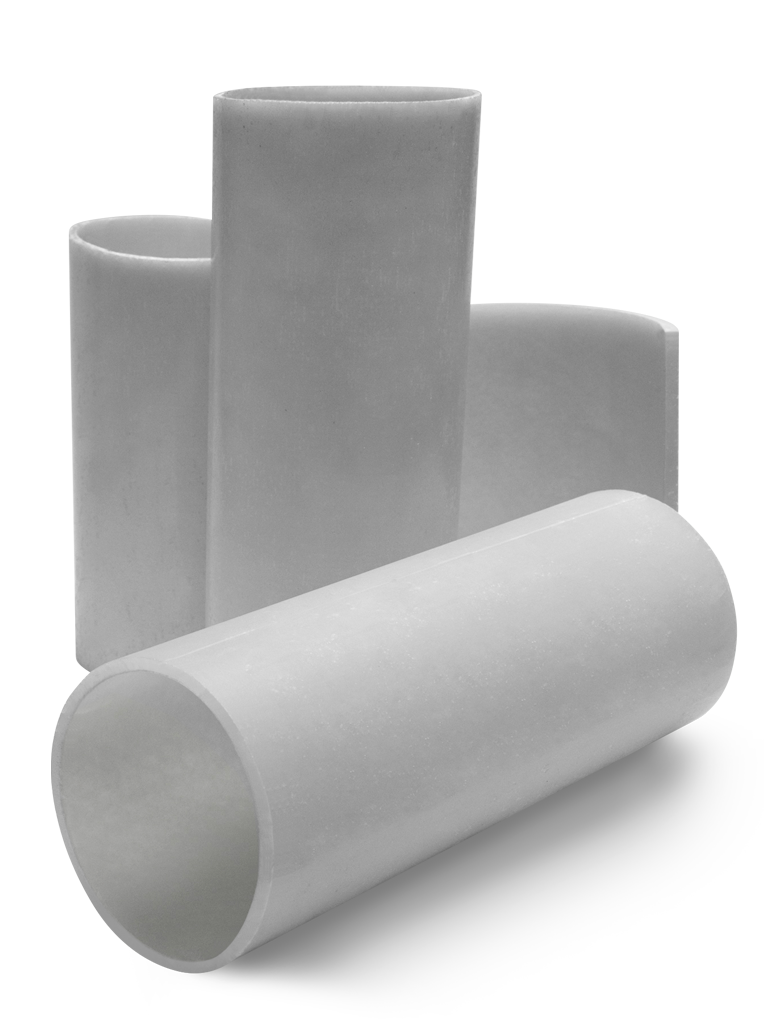

Over 300km worldwide installation length of

PAA-F-Liners per year

Over 700 tons styrene free resin per year

02

Proven and documented process safety

03

Environmentally friendly resin, odorless and

low-emission technology

04

High-quality result:

top end-product with at least 50 years lifetime

05

Process technology approved by DIBT (Germany), WRC (UK) and CSTB (France)

06

More than 15 years practical development experience and on-site track record

07

Perfectly matched and harmonized LED light sources and CIPP materials out of one manufacturer

08

Between 90% and 99% CO2 savings compared to heat-curing systems

09

Minimum installation time, quick recommissioning of the renovated sections